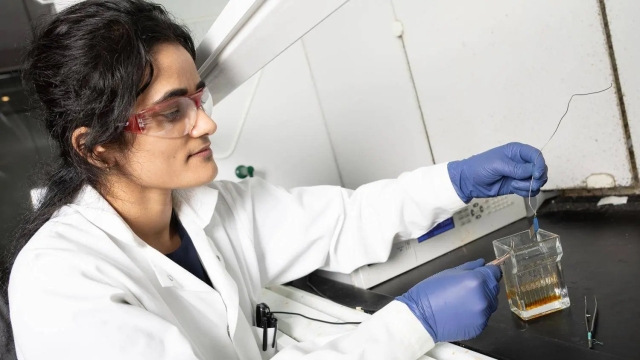

Image: Candler Hobbs/Georgia Tech

An electrochemical process developed at Georgia Tech could offer new protection against bacterial infections without contributing to growing antibiotic resistance.

The approach capitalizes on the natural antibacterial properties of copper and creates incredibly small needle-like structures on the surface of stainless steel to kill harmful bacteria like E. coli and Staphylococcus. It’s convenient and inexpensive, and it could reduce the need for chemicals and antibiotics in hospitals, kitchens, and other settings where surface contamination can lead to serious illness.

The team first developed an electrochemical method to etch the surface of stainless steel, creating nano-sized needle-like structures on the surface that can puncture bacteria’s cell membranes. Then, with a second electrochemical process, the researchers deposited copper ions on the steel’s surface. Copper interacts with the cell membranes and ultimately compromises them.

Despite copper’s known antibacterial properties, it’s not widely used to fight surface contamination because it’s expensive. Tripathi’s approach deposits only a thin layer of copper ions on the stainless steel, so it’s cost-effective without compromising the material’s antibacterial activity.

Together, the dual attacks resulted in 97% reduction of Gram-negative E. coli and 99% reduction in Gram-positive Staphylococcus epidermis bacteria in the group’s study.

Source: Georgia Tech

Image: Candler Hobbs/Georgia Tech